Of the many decisions you need to make about a custom medical cart, determining the production process may not be your top priority.

However, knowing how a custom medical cart is intended to be produced helps you identify details that may affect your concept cart design and any proposed changes made throughout production.

Finding a medical cart manufacturer with a made to order policy — think of it as "carts by design" — gives you the opportunity to change your concept cart throughout production. This level of efficiency saves time and money, and it also comes with a few other perks.

Improving Custom Medical Carts Throughout Production

As manufacturers and vendors continue to struggle with pandemic-related supply chain disruptions and a skilled labor shortage, medical device manufacturers must exercise as much control over their cart design and production as possible.

Working with a cart manufacturer that has a made to order policy provides both design control and latitude that medical device manufacturers need. It also contributes to responsiveness in creating a competitive advantage since:

- Changes — and even changes to changes — can be made while the cart is in production

- There are no stocked older versions of finished medical carts that must be managed, scrapped, or liquidated due to inventory obsolescence

- Continuous improvement is inherent in the "carts by design" approach

From an engineering standpoint, a made to order policy is valuable for implementing "on the fly" design changes that are often critical to cart integrity and safety. Being able to make modifications right up to a scheduled production run deadline both improves designs and prevents potentially costly errors.

4 Advantages of HUI Made to Order Manufacturing

Our proven success in made to order production has earned HUI preferred status among many medical device manufacturers. In addition to continuous improvement opportunities for design and seamlessness of production, we offer strategic value-adds that help our customers manage time and budgets:

1. Better Cash Flow

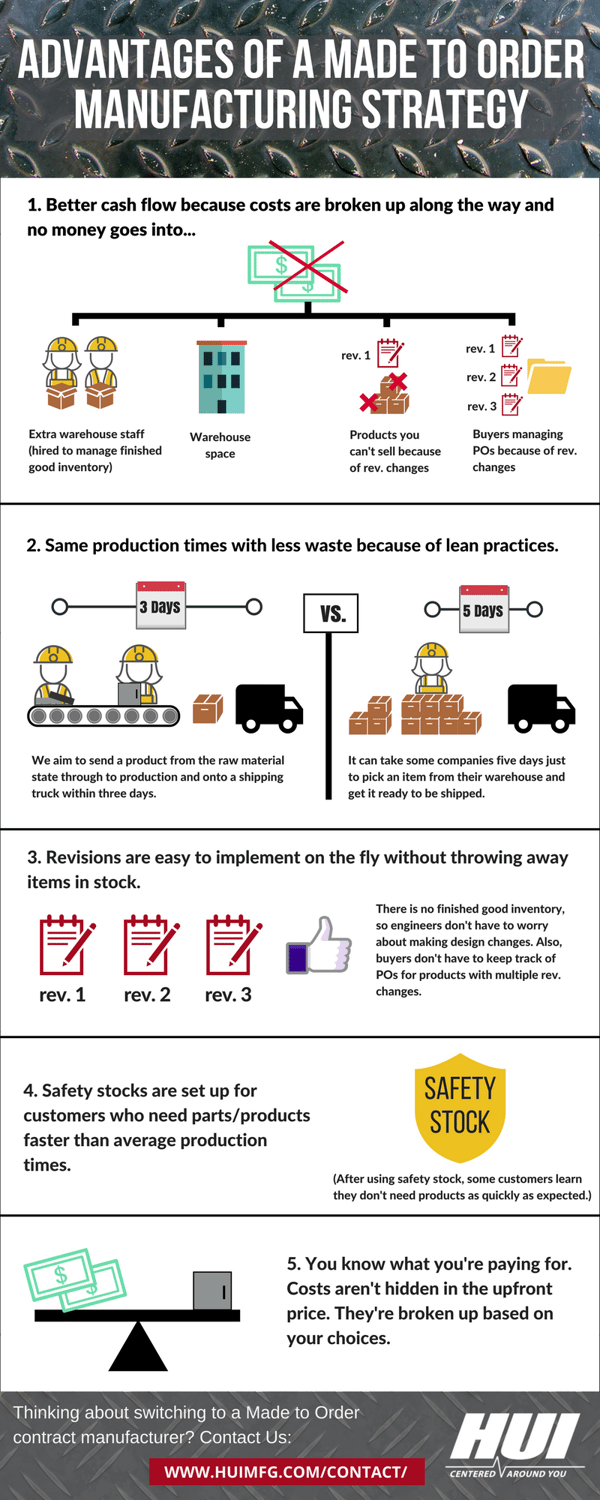

Customers can readily manage and reduce working capital under a made to order policy. There's the flexibility of having carts built as they're needed, plus there's no budget dollars allocated to holding surplus finished inventory and the related warehousing expenses.

2. Less Warehouse Waste

One of the greatest advantages of a made to order policy is eliminating the extra fees associated with warehouse space and staff. Using lean practices enables HUI to eliminate the "middle man." Medical carts are sent through production and straight to shipping without ever being placed in finished good inventory.

3. Production Time Equivalence

Some customers worry that lead times are compromised because HUI doesn't hold inventory. However, since orders are able to be placed in advance and modified throughout the process, the production time isn’t any different from companies that hold inventory. Sometimes it’s even shorter.

It comes down to how that production time is used. For us, the goal is to take a medical cart project from the raw material stage through to production and onto a shipping truck within three days. Conversely, it could take other companies five days just to pick an item from their warehouse and get it ready to ship.

4. Safety Stock

Safety stock is a fee-based option for those customers who need parts faster than average production times. Safety stock may be created if a customer needs parts from an outside supplier that has excessive lead times, or if a customer needs a medical cart built quicker than HUI's standard three-day production time. Safety stock is flexible. If a customer learns they don’t need carts as quickly as expected, we can remove items from safety stock.

Partnering with a medical cart manufacturer that implements a made to order policy helps you leverage many advantages, not the least of which is cost containment. Learn more about how align this manufacturing strategy with budgetary needs in our eBook, How to Design Your Custom Medical Cart to Meet a Specific Price Point.